Laser engraving has emerged as one of the most versatile and precise fabrication techniques of the modern age. Driven by rapid advances in laser technology, computer-aided design, and motion control systems, laser engravers and cutters have become remarkably accessible tools for artists, makers, and small business owners. But behind the simple push-button operation of these devices lies a fascinating interplay of applied physics, optical engineering, and software automation.

In this article, we’ll explore the scientific principles that enable laser engraving and cutting, the different types of laser systems in use, common applications, how to work with laser engravers, and the creative possibilities this technology enables.

Table of Contents

The Science of Laser Engraving

At its core, laser engraving relies on the focused energy beam of a laser, or “Light Amplification by Stimulated Emission of Radiation,” to selectively remove material with incredible precision. But how does this process actually work?

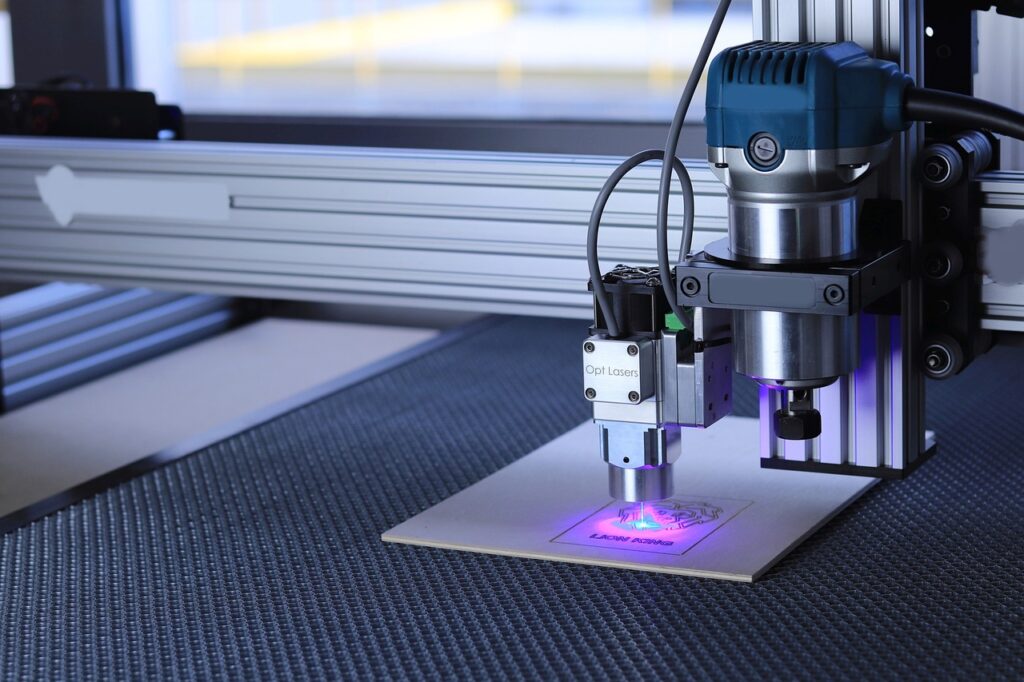

When a laser beam hits the surface of a material, the intense light energy is absorbed by the material, instantly heating a microscopic region and causing rapid vaporization. This ablates away a tiny amount of material precisely following the laser path.

By controlling the laser with mirrors on fast-moving galvanometers, variable speed motors, and computer generated patterns, this vaporization process can be directed along practically any path to “draw” a design. Resolution better than 0.005 inches is possible.

Lasers used for engraving are typically in the 10 to 100 Watt power range for optimal balance of precision and cutting/engraving speed. Materials like wood, leather, plastic, acrylic and some metals absorb the laser wavelength very efficiently, making them ideal for laser engraving.

Popular Laser Types

Various laser technologies are used in engraving systems, each with pros and cons:

- CO2 lasers use a mix of carbon dioxide, nitrogen and helium as the lasing medium. They operate at a wavelength readily absorbed by organic materials. CO2 lasers provide the best balance of power and cost for cutting and engraving non-metals.

- Fiber lasers use a seed laser pumped into an optical fiber lasing medium. They generate a near-infrared wavelength suited for marking metals. Fiber lasers are more expensive but deliver high powers up to 10 kilowatts.

- Diode lasers consist of semiconductor diodes that produce a visible or near-infrared wavelength when electrically pumped. Diode lasers are inexpensive, compact, and draw little power. This makes them well suited for smaller desktop engraving systems.

- Green laser variants utilize nonlinear optics to convert the output of other laser types into visible green light. The green wavelength offers finer resolution and works well on glass and crystal materials.

Versatile Applications

Thanks to this combination of precision and configurability, laser engravers enable a huge range of applications:

- Permanently marking parts with serial numbers, barcodes, logos or QR codes

- Custom engraving on materials like wood, acrylic, metal, leather, or glass

- Cutting 2D shapes and profiles out of sheet materials

- Selective material removal for surface texturing

- Etching beautiful artwork and photographs

- Cutting extremely intricate patterns and stencils

Lasers are commonly used by artists and craftspeople, schools and hobbyists, prototyping shops, and businesses needing custom marked or fabricated parts. If you can dream it up, there’s a good chance a laser can engrave, mark, or cut it!

Getting Started with Laser Engraving

Thanks to professional grade laser systems from companies like Creality Falcon, laser engraving and cutting have become accessible options for small businesses, artists’ studios, and home workshops.

Their proven, well-engineered CO2 and diode laser machines, like the Crelaity Halot Laser Engraver and the Laser Cutter, make getting professional results possible right out of the box.

Here’s a quick overview of how to get started with laser engraving:

1. Choose the Right Laser Machine

Consider your budget, work area needs, and material capabilities. Diode or CO2 lasers cover most non-metal materials. Go with higher power for cutting versus just engraving.

2. Pick Your Material

Laser engravable materials include wood, acrylic, leather, anodized aluminum, glass, cardboard, and more. Avoid PVC, polycarbonates, and other materials containing chlorine or halogens.

3. Design Your Pattern

Use vector and raster graphic software like Adobe Illustrator, Inkscape, GIMP, or CAD programs to design your pattern. Laser engravers work from digital image files.

4. Dial In Your Settings

Most laser systems include software to translate your designs into laser instructions. Choose the right speed, power, resolution, and mode settings for crisp results.

5. Send It!

With your design loaded and laser safely configured, simply hit go and watch your engraving or cutting job come to life!

Creative Applications

With somedesign experience and experimentation with settings, fantastically detailed and artistic laser engraved items are possible, like:

- Wood signs and wall art with photographic image reproduction

- Intricate mandalas and geometric patterns in acrylic

- Beautiful etchings on glassware and mirrors

- Whimsical designs on leather bags, wallets, and journals

- Custom corporate gifts like engraved pens, awards, and plaques

- Monogrammed jewelry made from engraved metal pendants

Anything that can be drawn in a digital file, can be engraved or marked using a laser. While initially intimidating, laser systems are surprisingly turnkey once setup. For artists,inventors, and craftspeople, laser engravers unlock a world of creative applications.

Laser engraving technology represents an incredibly flexible fabrication tool, made accessible by modern diode and CO2 laser systems. These computer-controlled engravers and cutters work like robotic arms holding pencils of pure light. By learning to harness them creatively, makers can unlock a whole new world of precision and possibilities.

So whether you’re an artist, entrepreneur, or hobbyist, consider bringing laser engraving in-house. The combination of art and science powering these devices makes them endlessly capable tools for creation.